The concept of a digital twin, once a theoretical construct in advanced engineering, is rapidly evolving into a practical, indispensable tool that is fundamentally reshaping how industries operate, how products are designed, and how complex systems are managed. This isn’t just about creating a 3D model; it’s about building a dynamic, real-time virtual replica of a physical asset, process, or system, enabling unprecedented insights, predictions, and optimizations. The phrase “Digital Twin Supremacy” highlights its growing dominance as a critical technology, while “Virtualizing Reality” underscores its core function: bringing the complexities of the physical world into a highly actionable digital realm. This article delves deep into the multifaceted ways digital twins are driving this transformation, exploring their foundational principles, transformative applications across diverse sectors, and the significant challenges and profound opportunities they present for a future where intelligent, virtual replicas are paramount to real-world success.

The Digital Twin Fundamentals

To truly grasp how digital twins are achieving supremacy by virtualizing reality, it’s essential to understand their core components and how they function as dynamic bridges between the physical and digital worlds.

A. Physical Asset or System: This is the real-world entity being mirrored. It can be anything from a single machine, a building, a wind turbine, an entire factory, a city, or even a human organ. The physical asset is the source of the data that feeds the digital twin.

B. Sensors and Data Collection: The physical asset is equipped with various sensors (IoT devices, cameras, LiDAR, accelerometers, temperature probes, etc.) that continuously collect real-time data about its performance, condition, environment, and behavior. This data is the lifeline connecting the physical to the digital.

C. Connectivity: A robust and often high-bandwidth connectivity layer (5G, Wi-Fi, fiber optics, LPWAN) is crucial to transmit the collected data from the physical asset to the digital twin platform in real-time or near real-time. Low latency is often critical for immediate insights and control.

D. The Digital Model: This is the virtual replica itself. It’s a complex, multi-faceted computer model that represents the physical asset’s geometry, physics, behavior, and operational state. It’s often built using:

* 3D Modeling and Simulation Software: For accurate visual and functional representation.

* Physics-Based Models: Simulating how the asset behaves under different conditions (e.g., stress, temperature, fluid flow).

* Mathematical Algorithms: Representing operational logic and performance characteristics.

E. Data Integration and Processing: The raw sensor data is ingested into the digital twin platform, where it is cleansed, integrated, and processed. This often involves combining real-time data with historical data, design data, and maintenance records to create a comprehensive picture of the asset.

F. Analytics and Artificial Intelligence (AI): The Brains of the Twin: This is where the magic happens. AI and Machine Learning (ML) algorithms are applied to the integrated data within the digital twin to:

* Monitor Performance: Continuously assess the asset’s health and operational efficiency.

* Diagnose Issues: Identify root causes of anomalies or failures.

* Predict Failures: Forecast when maintenance will be needed (predictive maintenance).

* Optimize Operations: Suggest adjustments to improve performance, efficiency, or safety.

* Simulate Scenarios: Run “what-if” scenarios to test changes without affecting the physical asset.

G. User Interface and Visualization: Digital twins are typically accessed through intuitive dashboards, 3D visualizations, and augmented reality (AR) or virtual reality (VR) interfaces, allowing users to interact with the virtual replica, view data, and gain actionable insights.

H. Feedback Loop and Actuation: A critical component is the feedback loop. Insights gained from the digital twin can be used to send commands or recommendations back to the physical asset, enabling real-time control, automated adjustments, or informed human intervention, thus completing the “closed loop” optimization.

Impact Across Diverse Sectors

The compelling capabilities of digital twins are driving their supremacy, profoundly impacting and virtualizing reality across a multitude of industries right now, enabling smarter decision-making and unprecedented operational control.

A. Manufacturing and Industrial Production: Smart Factories Unleashed: Digital twins are at the heart of Industry 4.0.

* Predictive Maintenance: Real-time data from machinery feeds its digital twin, which uses AI to predict potential equipment failures before they occur. This allows for scheduled maintenance, avoiding costly unplanned downtime and optimizing asset lifespan.

* Process Optimization: Digital twins of entire production lines simulate different scenarios to identify bottlenecks, optimize workflow, and improve throughput and efficiency without disrupting physical operations.

* Quality Control: Monitoring the performance of manufacturing processes in real-time via digital twins helps detect deviations from quality standards instantly, allowing for immediate corrective action and reducing defects.

* Remote Monitoring and Control: Operators can monitor and control complex industrial assets globally from a central location through their digital twins, enhancing operational flexibility and safety, especially for hazardous environments.

* New Product Development: Creating digital twins of new products during the design phase allows for extensive virtual testing and simulation before physical prototyping, accelerating time-to-market and reducing development costs.

B. Smart Cities and Urban Planning: Intelligent Urban Ecosystems: Digital twins are crucial for managing the complexity of modern cities.

* Urban Planning and Development: Creating digital twins of entire cities or districts allows urban planners to simulate the impact of new infrastructure (buildings, roads), population growth, or climate change on traffic, energy consumption, and environmental factors, optimizing city design.

* Traffic Management: Real-time digital twins of transportation networks can simulate traffic flow, predict congestion, and optimize traffic light timings or public transport routes to improve urban mobility.

* Infrastructure Monitoring: Digital twins of bridges, tunnels, and utilities can monitor their structural integrity and performance, predicting maintenance needs and enhancing safety and resilience.

* Energy Optimization: Simulating energy consumption patterns in buildings and city grids allows for optimized resource allocation and integration of renewable energy sources, leading to more sustainable cities.

C. Healthcare and Life Sciences: Precision Health and Patient Care: Digital twins are extending into the realm of human biology.

* Digital Twin of a Patient (Human Digital Twin): Creating a virtual replica of an individual’s organs, physiological systems, or even their entire body, based on their unique genomic data, medical history, and real-time wearable data. This enables personalized medicine, predicting disease progression, and simulating treatment responses before administering them to the patient.

* Surgical Planning and Simulation: Digital twins of patient anatomies allow surgeons to practice complex operations in a virtual environment, minimizing risks and improving outcomes.

* Drug Discovery and Development: Simulating drug interactions with digital twins of cells or organs can accelerate drug discovery, predict efficacy, and identify potential side effects early in the development process.

* Medical Device Optimization: Digital twins of medical devices (e.g., pacemakers, prosthetics) can monitor their performance in real-time, predict maintenance needs, and optimize their function based on patient data.

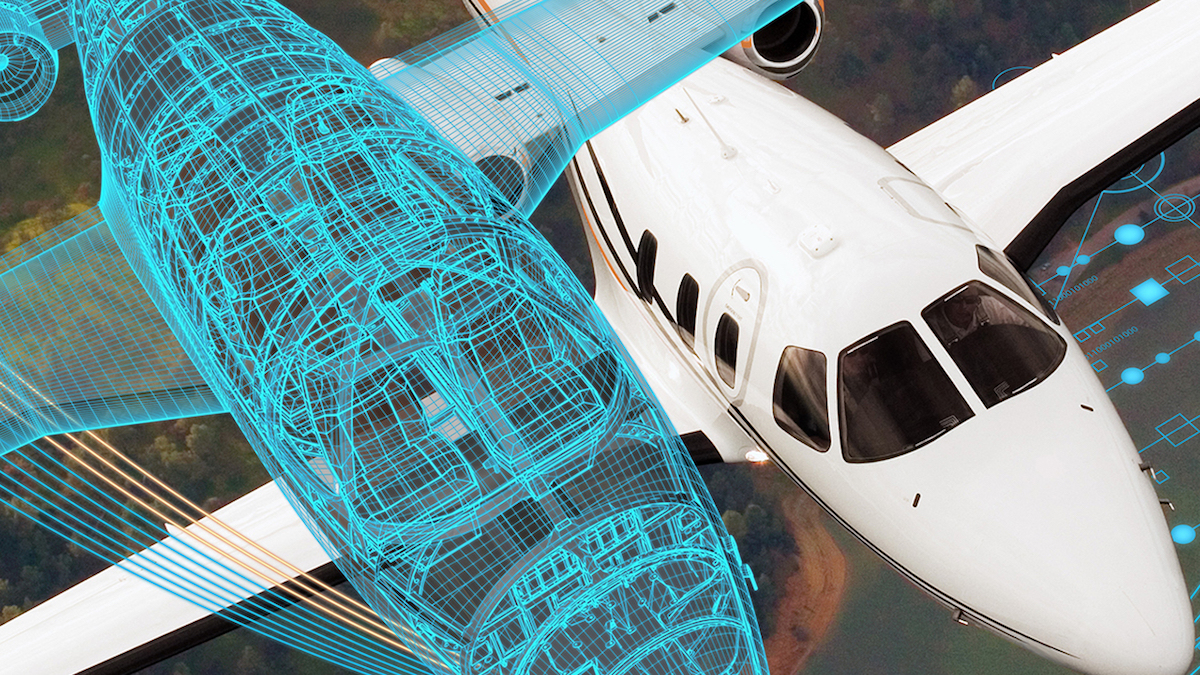

D. Aerospace and Defense: Performance and Safety Optimization: Digital twins have been used in aerospace for decades and are becoming more sophisticated.

* Aircraft Performance Monitoring: Digital twins of aircraft engines or entire planes continuously monitor performance, detect anomalies, predict maintenance needs, and optimize fuel efficiency during flight.

* Fleet Management: Managing an entire fleet of aircraft or drones through their digital twins allows for optimized scheduling, maintenance, and resource allocation.

* Satellite Operations: Digital twins of satellites can simulate orbital maneuvers, predict equipment failures, and optimize data transmission, ensuring efficient and reliable operation in space.

E. Automotive Industry: Design, Manufacturing, and Autonomous Vehicles:

* Vehicle Design and Testing: Digital twins of new car models allow for virtual crash testing, aerodynamic simulations, and performance optimization before physical prototypes are built, significantly reducing development cycles and costs.

* Connected and Autonomous Vehicles (CAVs): Digital twins of CAVs interact with digital twins of road infrastructure and traffic systems to simulate complex scenarios, train AI drivers, and optimize routing and safety in real-time.

* Manufacturing Plant Optimization: Digital twins of entire automotive factories help simulate production flows, optimize robot movements, and predict bottlenecks.

F. Retail and Customer Experience: Smart Stores and Supply Chains:

* Smart Store Operations: Digital twins of retail spaces can simulate customer flow, optimize product placement, and manage inventory in real-time, enhancing customer experience and operational efficiency.

* Supply Chain Resilience: Creating digital twins of entire supply chains allows companies to simulate the impact of disruptions (e.g., natural disasters, geopolitical events) and optimize routes or inventory to maintain resilience.

G. Energy and Utilities: Grid Resilience and Resource Optimization:

* Power Grid Management: Digital twins of electrical grids monitor energy flow, predict demand fluctuations, integrate renewable sources, and simulate responses to outages, enhancing grid stability and resilience.

* Wind Turbine Optimization: Digital twins of individual wind turbines monitor their performance, predict maintenance, and optimize blade pitch in real-time to maximize energy capture based on wind conditions.

* Oil and Gas Operations: Digital twins of drilling rigs, pipelines, and refineries monitor equipment health, optimize operations, and predict potential hazards, improving safety and efficiency in hazardous environments.

The Apex of Virtualization

The pervasive adoption of digital twin technology isn’t just a technical achievement; it’s catalyzing profound societal and economic shifts, reshaping labor markets, investment patterns, and the very nature of decision-making.

A. Enhanced Operational Efficiency and Cost Savings: By enabling predictive maintenance, process optimization, and virtual prototyping, digital twins lead to significant reductions in operational costs, downtime, waste, and development cycles, boosting profitability.

B. Increased Safety and Risk Mitigation: Simulating hazardous conditions or complex operations in a virtual environment via digital twins reduces risks for human workers, prevents accidents, and allows for proactive identification of potential failures in critical systems, enhancing overall safety across industries.

C. Accelerated Innovation and Time-to-Market: The ability to rapidly test and iterate designs virtually allows companies to innovate faster, bring new products and services to market quicker, and maintain a competitive edge.

D. New Business Models and Service Offerings: Digital twins enable entirely new service models, such as “performance-as-a-service” (where customers pay based on asset uptime optimized by its digital twin) or advanced remote diagnostics and maintenance services. This also creates opportunities for new specialized consulting and technology firms.

E. Data-Driven Decision Making at Scale: Digital twins provide an unprecedented level of real-time, comprehensive data and predictive insights, allowing organizations to make more informed, data-driven decisions across all levels of operation and strategy, moving from reactive to proactive management.

F. Workforce Transformation and Upskilling: While some routine tasks may be automated, digital twins create demand for new roles in data science, AI engineering, digital twin modeling, virtual commissioning, and highly skilled operators who can interpret and act on insights from these sophisticated virtual replicas. This necessitates a focus on upskilling and reskilling programs.

G. Environmental Sustainability: By optimizing energy consumption, reducing material waste, extending asset lifespans, and enabling more efficient resource management, digital twins contribute significantly to environmental sustainability goals across various sectors.

H. Ethical Considerations and Data Governance: The vast amount of data collected by digital twins, especially human digital twins, raises significant ethical concerns regarding data privacy, surveillance, and algorithmic bias. Robust data governance frameworks, consent mechanisms, and transparent data use policies are crucial.

Navigating Challenges and Future Trajectories

Despite their growing supremacy, the journey of digital twins is not without its complexities. Overcoming these hurdles will be crucial for their continued expansion and for fully realizing their transformative potential across all facets of reality.

A. Data Integration and Interoperability: Integrating diverse data streams from myriad sensors, legacy systems, and different vendors into a coherent digital twin model is a major challenge. Lack of standardized data formats and interoperability protocols can hinder comprehensive twin creation.

B. Computational Power and Scalability: Creating and maintaining real-time digital twins of complex systems or entire cities requires immense computational power, storage, and networking capabilities. Scaling these solutions economically remains a significant hurdle.

C. Cybersecurity of Connected Systems: The highly interconnected nature of digital twins, linking physical assets to digital models and control systems, presents a vast cybersecurity attack surface. Protecting sensor data, twin models, and control commands from malicious actors is paramount.

D. Accuracy and Fidelity of Models: The usefulness of a digital twin hinges on the accuracy and fidelity of its virtual model to the physical asset. Developing increasingly sophisticated physics-based models, continuously updating them with real-world data, and validating their predictions are ongoing challenges.

E. Cost of Implementation: While digital twins offer significant long-term ROI, the initial investment in sensors, connectivity, software platforms, and skilled personnel can be substantial, particularly for complex deployments across large organizations.

F. Lack of Talent and Expertise: There’s a significant talent gap for professionals skilled in digital twin development, AI integration, data science for industrial applications, and managing these complex cyber-physical systems. Educational initiatives are crucial.

G. Ethical and Regulatory Frameworks: As digital twins become more pervasive, especially for human or critical infrastructure applications, developing clear ethical guidelines and regulatory frameworks for their use, data ownership, liability, and decision-making autonomy is vital.

H. Predictive Maintenance for Complex Systems: While basic predictive maintenance is common, developing highly accurate and reliable prediction models for the failure of incredibly complex systems with multiple interacting components remains an advanced challenge.

I. Digital Twin of Everything (Convergence): The future envisions a “digital twin of everything” – interconnected twins of products, processes, people, and environments. This requires seamless integration and communication between disparate twins, creating a global “mirror world” that facilitates unprecedented insights and control.

J. Real-Time Actuation and Autonomous Optimization: Moving beyond just insights, the future will see digital twins increasingly enabling real-time, autonomous optimization and control of physical assets, where the twin directly communicates adjustments to the physical system without human intervention, leading to fully self-optimizing systems.

Conclusion

Digital twin technology is asserting its supremacy by brilliantly virtualizing reality, transforming isolated physical assets into intelligent, interconnected digital counterparts. From revolutionizing manufacturing efficiency and enabling safer urban planning to personalizing healthcare and optimizing complex aerospace systems, its impact is profound and tangible. While significant challenges related to data integration, cybersecurity, and scalability persist, the undeniable benefits of enhanced operational efficiency, accelerated innovation, and unparalleled predictive capabilities are driving its rapid adoption across virtually every industry. By strategically investing in robust platforms, fostering interdisciplinary talent, and establishing clear ethical guidelines, we can collectively unlock the full promise of digital twin technology. The future is being built not just in the physical world, but also in its indispensable, dynamic virtual mirror, leading to a smarter, more efficient, and supremely optimized reality for all.

Discussion about this post