The relentless march of robotics is fundamentally reshaping the global industrial landscape. What began as specialized automation tools in factories has evolved into sophisticated, intelligent machines capable of complex tasks, collaborative work, and unprecedented levels of precision. Far from being confined to manufacturing lines, robots are now permeating diverse sectors, driving efficiencies, enhancing safety, and unlocking new possibilities previously unimaginable. This isn’t just an incremental improvement; it’s a profound transformation of how industries operate, paving the way for a more productive, innovative, and automated future. This article delves deep into the multifaceted ways robotics is transforming industries, exploring its impact from enhancing productivity to creating new economic paradigms.

The Evolution of Robotics

To truly grasp the significance of robotics’ current impact, it’s essential to understand its journey from rudimentary machines to highly intelligent and autonomous systems. This evolution has been driven by advancements in artificial intelligence, sensor technology, and mechanical engineering.

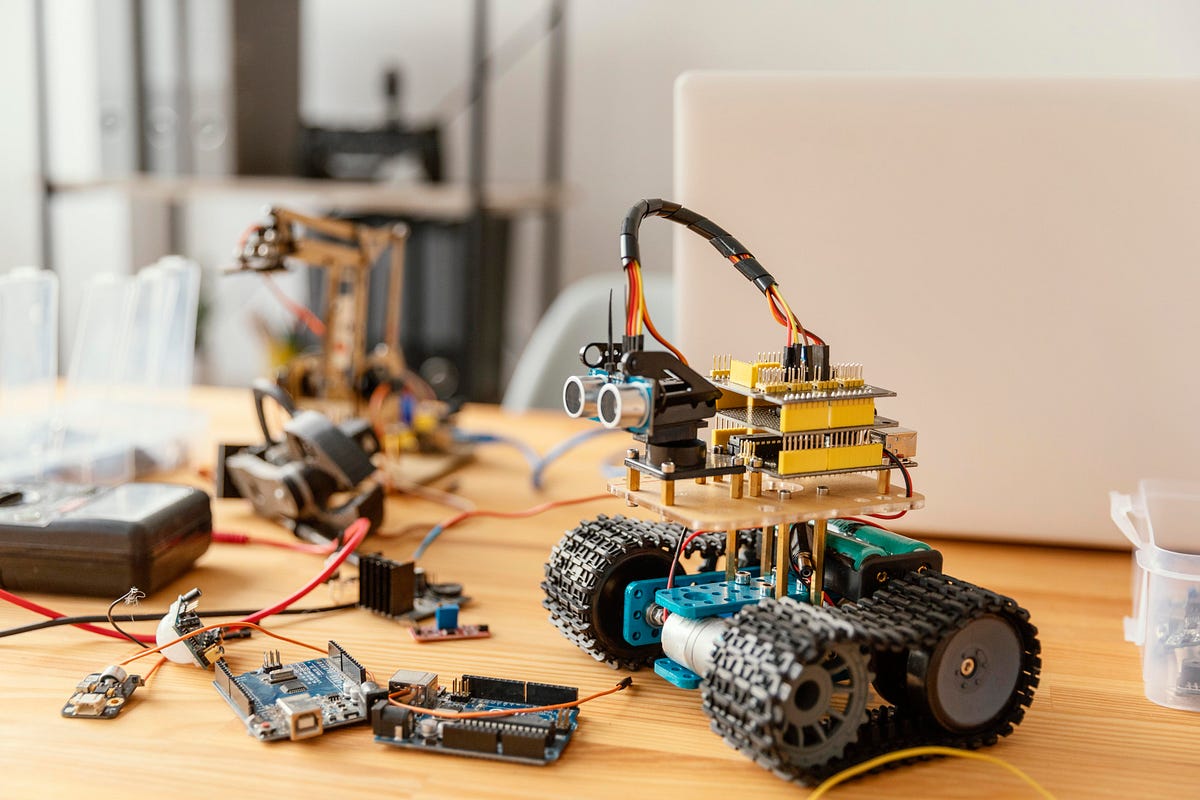

A. Early Industrial Robots: The genesis of industrial robotics can be traced back to the 1960s with the introduction of the Unimate, a programmable manipulator designed for repetitive tasks in automotive factories. These early robots were primarily “dumb” machines, programmed to perform fixed sequences of movements. Their value lay in consistency, endurance, and their ability to handle dangerous or monotonous tasks, laying the groundwork for widespread automation.

B. Programmable and Sensor-Driven Robots: The 1980s and 90s saw the emergence of more sophisticated, programmable robots equipped with basic sensors. This allowed them to adapt to minor variations in their environment and perform a wider range of tasks, from welding and painting to assembly. The introduction of vision systems started to give robots a rudimentary “sense of sight,” enabling them to identify and manipulate objects with greater accuracy.

C. Collaborative Robots (Cobots): A significant leap occurred with the development of collaborative robots, or cobots. Unlike traditional industrial robots that require safety cages, cobots are designed to work alongside human operators, sharing the same workspace safely. Equipped with advanced sensors and intelligent programming, they can detect human presence and stop or slow down, making human-robot interaction seamless and efficient. This has opened up new applications in small and medium-sized enterprises (SMEs) and tasks requiring human dexterity combined with robotic strength.

D. Autonomous Mobile Robots (AMRs): Beyond stationary manipulators, the rise of Autonomous Mobile Robots (AMRs) has revolutionized logistics and warehousing. Unlike Automated Guided Vehicles (AGVs) which follow fixed paths, AMRs navigate independently using onboard sensors, maps, and advanced algorithms. They can transport goods, manage inventory, and optimize routes in real-time, significantly improving efficiency and flexibility in complex environments.

E. AI-Powered and Swarm Robotics: The integration of Artificial Intelligence (AI) is the current frontier, transforming robots from mere machines into intelligent agents. AI enables robots to learn from experience, make complex decisions, perceive and understand their environment with greater nuance, and even interact with humans using natural language. The concept of swarm robotics, where multiple simple robots coordinate to achieve complex tasks, further expands possibilities, particularly in areas like exploration, construction, and disaster response.

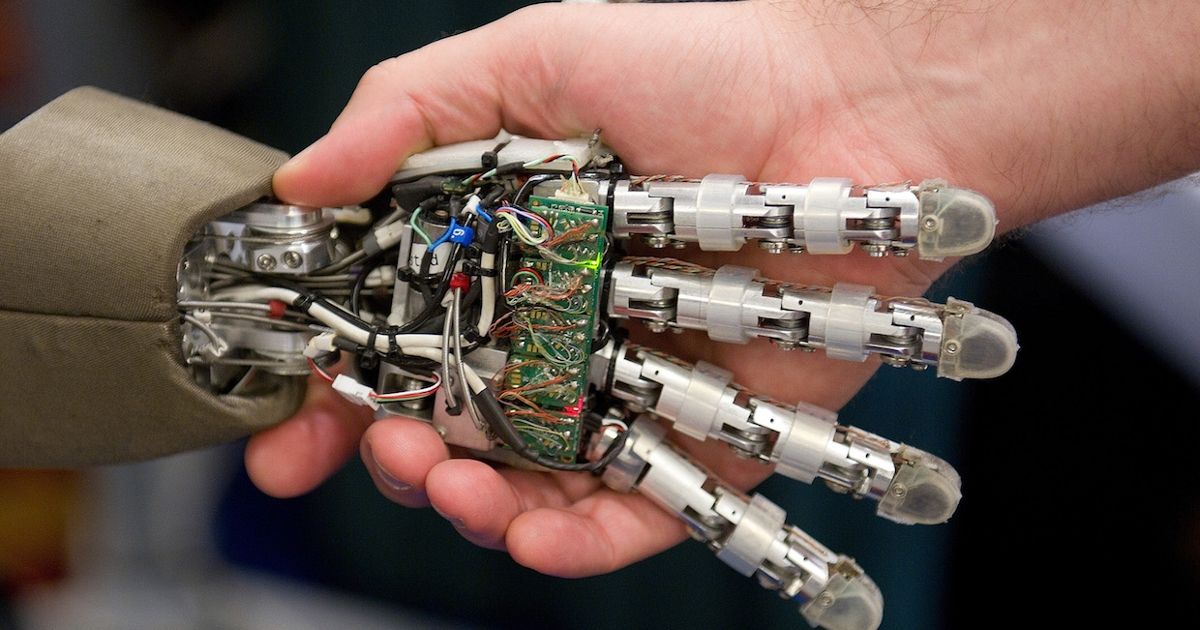

F. Soft Robotics and Bio-Inspired Design: Pushing the boundaries further, soft robotics focuses on creating robots from compliant, deformable materials, inspired by biological organisms. These robots are inherently safer for human interaction, more adaptable to irregular environments, and capable of delicate manipulation. Bio-inspired designs, drawing lessons from nature’s efficiency and resilience, are leading to robots that can walk, swim, fly, and even heal themselves.

Redefining Industrial Paradigms

The transformative power of robotics is most evident in its ability to redefine established industrial practices, creating new efficiencies, optimizing processes, and fostering entirely new business models across a diverse array of sectors.

A. Manufacturing and Assembly Reinvented: This is the birthplace of industrial robotics, and it continues to be a primary area of transformation. Advanced robotic assembly lines are now capable of handling intricate products with extreme precision and speed, reducing defects and increasing output. Flexible manufacturing systems, where robots can be quickly reprogrammed for different products, allow for mass customization and shorter production cycles. Predictive maintenance, powered by robot data, minimizes downtime, leading to unprecedented levels of efficiency and agility in production.

B. Logistics and Warehousing Revolutionized: The e-commerce boom has made fast and efficient logistics paramount. Automated warehouses leverage AMRs, robotic arms for picking and packing, and sophisticated AI algorithms to manage inventory, sort packages, and fulfill orders with remarkable speed and accuracy. This reduces labor costs, improves throughput, and handles the sheer volume of goods in modern supply chains, making same-day delivery a reality.

C. Healthcare and Medical Applications Expanded: Robotics is profoundly impacting healthcare, enhancing patient care, improving surgical outcomes, and streamlining hospital operations. Surgical robots provide enhanced precision, dexterity, and visualization for surgeons, leading to less invasive procedures, faster recovery times, and reduced patient risk. Service robots assist with tasks like delivering medication, sterilizing rooms, and even providing companionship to elderly patients. Robotic exoskeletons are aiding in rehabilitation, helping patients regain mobility.

D. Construction and Infrastructure Accelerated: The construction industry, often slow to adopt new technologies, is seeing a surge in robotic applications. Automated bricklaying robots can construct walls rapidly and accurately. Drones equipped with robotic arms can inspect infrastructure and perform maintenance in hard-to-reach areas. Robotic excavators and demolition machines improve safety and efficiency on job sites. This promises faster, safer, and more sustainable construction projects.

E. Agriculture’s Smart Future: From planting to harvesting, agricultural robots are addressing labor shortages, increasing yields, and promoting sustainable farming practices. Robotic systems can precisely plant seeds, weed fields with minimal chemical use, monitor crop health, and pick delicate fruits and vegetables without damage. This leads to higher quality produce, reduced waste, and more efficient resource management, ensuring food security for a growing global population.

F. Energy Sector Safety and Efficiency: In the energy industry, robots are deployed in hazardous environments to perform inspections, maintenance, and repairs, significantly improving safety and reducing human exposure to risk. This includes robotics for nuclear power plant inspections, oil and gas pipeline monitoring, and maintenance of offshore wind turbines. Drones inspect power lines, while underwater robots service subsea infrastructure, making energy production safer and more reliable.

G. Retail and Customer Service Enhanced: Robots are increasingly appearing in retail environments, from inventory management robots that scan shelves and track stock levels to customer service robots that provide information and guide shoppers. In hospitality, robots can check guests in, deliver room service, and even prepare food. This enhances customer experience, frees human staff for more complex tasks, and optimizes store operations.

H. Environmental Monitoring and Cleanup: Robots are becoming crucial tools for environmental protection. Autonomous underwater vehicles (AUVs) can monitor ocean health, detect pollution, and map ecosystems. Drones are used for monitoring deforestation, wildlife populations, and tracking the spread of wildfires. Robotic systems are also being developed for waste sorting and hazardous waste cleanup, contributing to a cleaner and more sustainable planet.

The Societal Impact in Workforce, Ethics, and Beyond

Beyond their direct industrial applications, the widespread adoption of robotics carries significant societal implications, particularly concerning the workforce, ethical considerations, and the very nature of human-robot interaction.

A. Workforce Transformation and Upskilling: One of the most significant impacts of robotics is on the workforce. While robots automate repetitive and dangerous tasks, potentially leading to job displacement in some areas, they also create new jobs in robot design, programming, maintenance, and oversight. The shift necessitates a massive investment in upskilling and reskilling initiatives to equip workers with the necessary skills for a robot-augmented economy, emphasizing creativity, critical thinking, and human-robot collaboration.

B. Safety and Ergonomics Improvements: By taking over hazardous, strenuous, or repetitive tasks, robots significantly improve workplace safety and ergonomics. This reduces the incidence of injuries, musculoskeletal disorders, and exposure to toxic environments, leading to healthier and safer working conditions for human employees. This not only benefits workers but also reduces healthcare costs and increases overall productivity.

C. Ethical Considerations and Accountability: As robots become more autonomous and intelligent, profound ethical questions arise. Who is accountable when an autonomous robot makes a mistake or causes harm? How do we ensure that AI-powered robots are unbiased and fair in their decision-making? Discussions around robot ethics, legal frameworks, and regulatory guidelines are crucial to ensure that robotics development aligns with societal values and promotes human well-being.

D. Human-Robot Collaboration and Trust: The future of work will increasingly involve humans and robots working side-by-side. Building trust in robotic systems is paramount. This involves designing robots that are transparent in their actions, predictable in their behavior, and easy to interact with. Understanding the psychological aspects of human-robot interaction will be key to fostering effective and harmonious collaborative environments.

E. Economic Repercussions and Global Competitiveness: Countries and industries that strategically invest in robotics and automation stand to gain a significant competitive advantage. This can lead to increased productivity, lower production costs, and the ability to bring manufacturing closer to end-users (reshoring). However, it also raises questions about global economic equity and the potential for a widening gap between technologically advanced and less advanced regions.

F. New Business Models and Service Innovation: The proliferation of robotics is giving rise to entirely new business models. Robotics-as-a-Service (RaaS), where companies rent robot capabilities rather than purchasing expensive hardware, is gaining traction. This lowers the barrier to entry for businesses, particularly SMEs. Furthermore, robots are enabling innovative service models in areas like last-mile delivery, personalized healthcare, and automated inspections.

Challenges, Trends, and Future Trajectories

Despite the rapid advancements, the field of robotics continues to face significant challenges, even as new trends emerge that will shape its future trajectory.

A. Cost and Accessibility: While the cost of robots is decreasing, particularly for cobots, the initial investment for complex robotic systems can still be substantial. Making robotics more affordable and accessible for a wider range of businesses, especially SMEs, is crucial for broader adoption. The rise of RaaS models is addressing this to some extent.

B. Integration and Interoperability: Integrating diverse robotic systems with existing industrial infrastructure and IT systems can be complex. Ensuring interoperability between different robot manufacturers, software platforms, and sensors is a major challenge. Standardized communication protocols and modular robot designs will be key to simplifying deployment.

C. Energy Efficiency and Power Sources: For mobile and autonomous robots, energy efficiency and reliable power sources are critical. Developing long-lasting batteries, efficient motors, and energy-harvesting technologies will enhance robot autonomy and operational duration, particularly for tasks in remote or challenging environments.

D. Adaptability to Unstructured Environments: While robots excel in structured, repetitive environments, navigating and operating effectively in highly unstructured or dynamic environments remains a challenge. Advances in perception, manipulation, and decision-making capabilities (driven by AI) are crucial for robots to handle variability and uncertainty.

E. Robustness and Resilience: Robots need to be robust enough to operate reliably in harsh industrial environments and resilient to unexpected failures. Developing self-diagnosing and self-healing robotic systems will minimize downtime and maintenance requirements, ensuring continuous operation.

F. Addressing Public Perception and Trust: Public perception of robots varies widely. Addressing concerns about job displacement, promoting the benefits of robotics, and showcasing successful human-robot collaboration are important for widespread societal acceptance and fostering a positive outlook towards automation. Transparent communication about robot capabilities and limitations is key.

G. The Rise of Hyper-Automation: The future points towards hyper-automation, where robotics, AI, process automation, and other emerging technologies are synergistically combined to automate virtually every process within an organization. This will create highly agile, efficient, and intelligent enterprises.

H. Beyond the Factory Floor: Expect to see robots in increasingly diverse roles: in homes for assistance and companionship, in urban environments for last-mile delivery, in dangerous jobs like firefighting and search-and-rescue, and even in space exploration, performing tasks too risky or remote for humans.

Conclusion

Robotics is no longer a futuristic concept; it is a present reality that is profoundly transforming industries across the globe. From boosting productivity and efficiency in manufacturing and logistics to enhancing safety in hazardous environments and revolutionizing healthcare, the impact is pervasive. While challenges related to workforce adaptation, ethical considerations, and technological hurdles persist, the relentless pace of innovation in AI, sensors, and materials science ensures that the capabilities of robots will continue to expand exponentially. By embracing thoughtful development, investing in human-robot collaboration, and establishing robust ethical frameworks, we can harness the immense power of robotics to create a more prosperous, sustainable, and technologically advanced future for all. The industrial landscape is being redefined, and robots are at the forefront of this exhilarating revolution.

Discussion about this post